What is galvanization of metal?

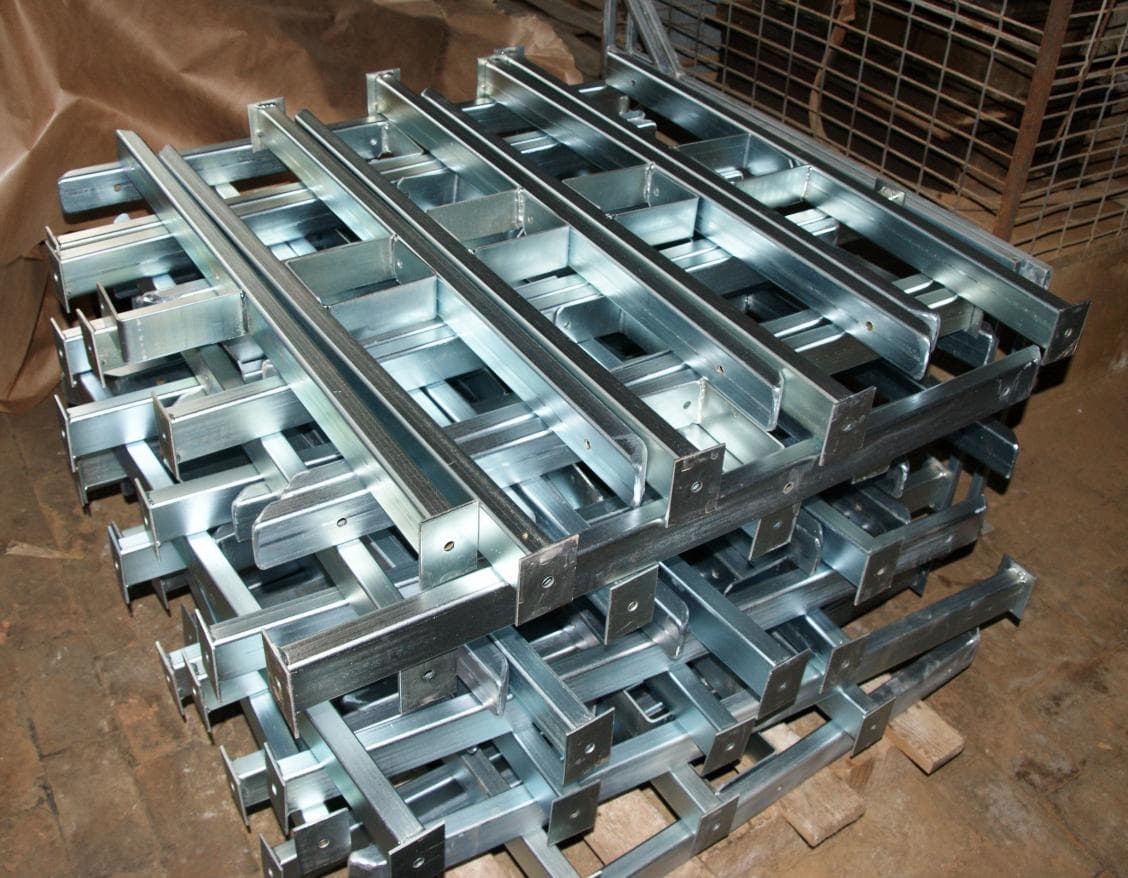

Punto Group is one of the few companies in Russia that galvanizes each of its products. This procedure is very important in the production of outdoor furniture, because thanks to it, 100% corrosion protection is achieved and each product will serve you for a long time.

The main advantages of metal structures galvanizing

Galvanizing is selected to process metal structures because of its advantages which make this technology much better than the others:

DurabilityIf the product is galvanized, it serves much longer than a product that was not protected from corrosion;

QualityOver time corrosion can cause great damage to the metal structure, making it more fragile. It is the galvanizing process that makes the metal product more qualitative;

VersatilityAlmost all metal structures can be galvanized. Due to all these advantages, hot-dip galvanizing services are often used in urban construction.

Stages of metal galvanization

Only at first glance galvanizing is a simple procedure. In fact, the technology includes 5 stages, each of them is of great importance and influences the final result.

1. Degreasing. Metal constructions should be thoroughly cleaned from greasy stains or oils in order to create a reliable protection against corrosion.

2. Etching. At this stage the metal is cleaned of the already accumulated corrosion. It is important for parts that have already been in operation.

3. Washing. Removes various particles left after etching.

4. Drying. Specialists heat the product with the help of special equipment up to 100 degrees. Due to the high temperature, the flux salts are drying.

5. And, finally, the process of galvanizing. As we noted above, the product is completely immersed in molten zinc, due to which it acquires a zinc sheath. It should be noted that all processes occur exclusively in technological conditions, where objects are placed into special tanks.